Dry Transformer and Oil Immersed Transformer Manufacturer

News

The Differences Between Oil Immersed Transformer and Dry Transformer

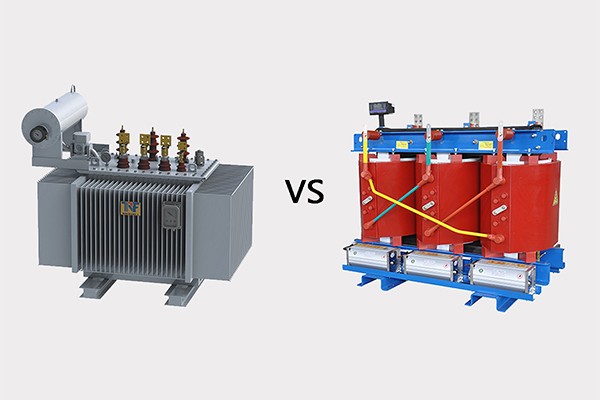

Oil immersed transformers and dry transformers are two common types of transformers used in electrical power systems. Both types of transformers serve the same basic function of stepping up or stepping down voltage levels, but there are also some differences between them.

A Brief Introduction to Oil Immersed Transformers

Oil immersed transformers, as the name suggests, use oil as a cooling and insulating medium. The oil helps to dissipate heat generated during operation and provides insulation between the transformer windings. This type of transformer requires regular maintenance to monitor the condition of the oil and replace it when necessary. The oil also helps to protect the transformer from moisture and contaminants, extending its lifespan.

A Brief Introduction to Dry Transformers

In contrast, dry transformers use air or solid insulation instead of oil. This eliminates the need for oil maintenance and reduces the risk of oil leaks or spills. Dry transformers are typically smaller and lighter than oil immersed transformers, making them easier to transport and install. However, they may have lower efficiency and be less suitable for high power applications.

The Differences Between Oil Immersed Transformer and Dry Transformer

One of the key differences between oil immersed transformers and dry transformers is their cooling methods. Oil immersed transformers rely on the oil to dissipate heat and keep the transformer operating at a safe temperature. The oil circulates through the transformer, absorbing heat from the windings and transferring it to the cooling system. In contrast, dry transformers use air or solid insulation to dissipate heat, relying on natural convection or forced air cooling to maintain the temperature within safe limits.

Another important difference between oil immersed transformers and dry transformers is their maintenance requirements. Oil immersed transformers require regular monitoring of the oil condition, including testing for moisture, acidity, and contaminants. The oil may need to be filtered or replaced periodically to ensure the transformer operates efficiently and reliably. In contrast, dry transformers have lower maintenance requirements, as there is no oil to monitor or replace. However, the insulation materials in dry transformers may degrade over time and require inspection or replacement to prevent insulation failure.

In terms of environmental impact, oil immersed transformers have the potential to leak oil, leading to soil and water contamination if not properly managed. Spills or leaks from oil immersed transformers can be costly to clean up and may pose a risk to human health and the environment. In contrast, dry transformers do not have the same risk of oil leaks or spills, making them a more environmentally friendly option.

When it comes to cost, oil immersed transformers are generally more expensive to purchase and maintain than dry transformers. The cost of the transformer itself, as well as the cost of oil maintenance and monitoring, can add up over the lifetime of the transformer. In contrast, dry transformers have lower initial costs and lower maintenance requirements, making them a more cost-effective option in the long run.

In terms of efficiency, oil immersed transformers and dry transformers can both achieve high levels of efficiency, depending on their design and operating conditions. Oil immersed transformers may have slightly higher losses due to the heat generated by the oil, but this can be mitigated by using high-quality materials and efficient cooling systems. Dry transformers may have lower losses due to the absence of oil, but their efficiency can be affected by the type of insulation used and the cooling method employed.

Conclusion

In conclusion, oil immersed transformers and dry transformers are two common types of transformers used in electrical power systems. While both types of transformers serve the same basic function of stepping up or stepping down voltage levels, they differ in terms of their construction, cooling methods, maintenance requirements, and suitability for different applications. Oil immersed transformers use oil as a cooling and insulating medium, while dry transformers use air or solid insulation. Oil immersed transformers require regular maintenance to monitor the condition of the oil, while dry transformers have lower maintenance requirements. Oil immersed transformers have the potential to leak oil and require careful management to prevent environmental contamination, while dry transformers are more environmentally friendly. Overall, the choice between oil immersed transformers and dry transformers depends on factors such as cost, maintenance requirements, environmental impact, and efficiency, as well as the specific requirements of the application.

Beiyoute has been in China for 20 years, and has accumulated rich experience and has a group of our own engineers. Beiyoute can provide you with a transformer solution that is suitable for you. If you have a demand, you can contact us, we will reply within 24 hours.

Main Product

Contact Us

- Sales Manager: Eric

- Phone: +86-15515007426

- Whatsapp: +86-15515007426

- Email: info@byttransformer.com

Featured Product