High and Low Voltage Switchgear

Menu

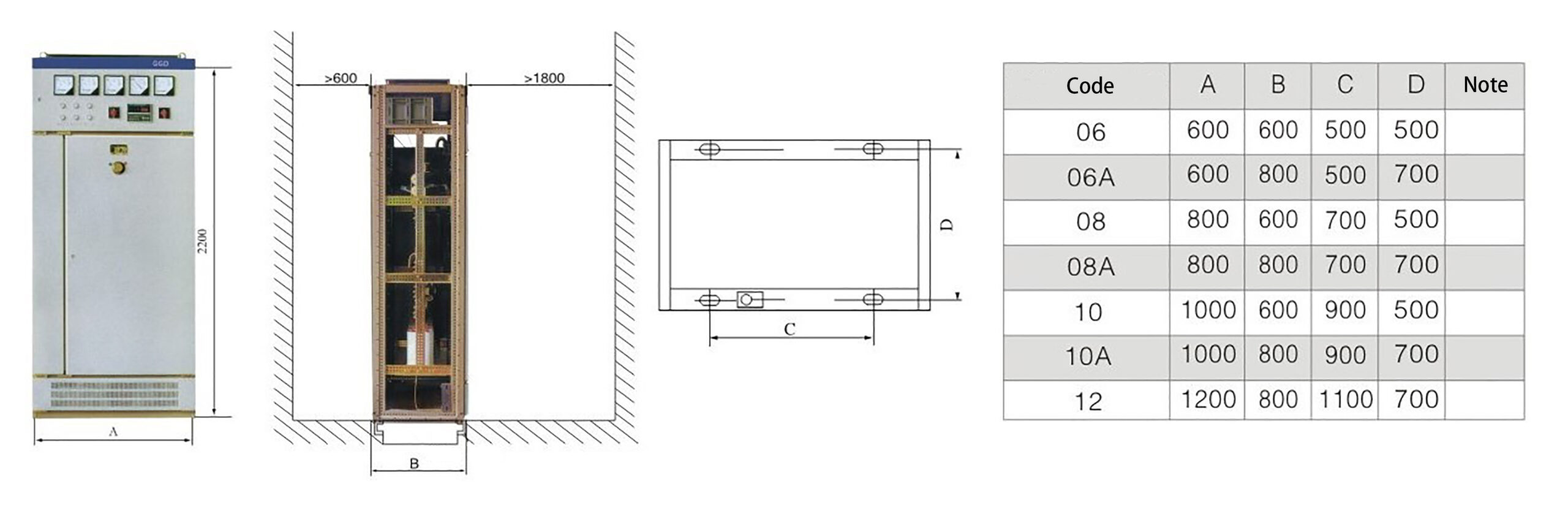

Low Voltage Switchgear GGD

- Ambient temperature: High temperature 45°C, low temperature -35°C

- Daily temperature difference: No more than 25°C

- Earthquake tolerance: Earthquake intensity does not exceed 8°C

The GGD low voltage switchgear is suitable for power users such as power plants, substations, and industrial enterprises. It is used in AC power distribution systems with a frequency of 50Hz (60Hz), a rated working voltage of 380V (400V) or 660V, and a rated current of up to 3150A for the conversion, distribution, and control of electrical energy for power and lighting equipment. This product features high breaking capacity, good dynamic and thermal stability, and a rated short-time withstand current of up to 50kA. It offers flexible electrical schemes, convenient combinations, strong practicality, innovative structure, and high protection levels.

Introduction of Low Voltage Switchgear GGD

Some structural features of Low Voltage Switchgear GGD:

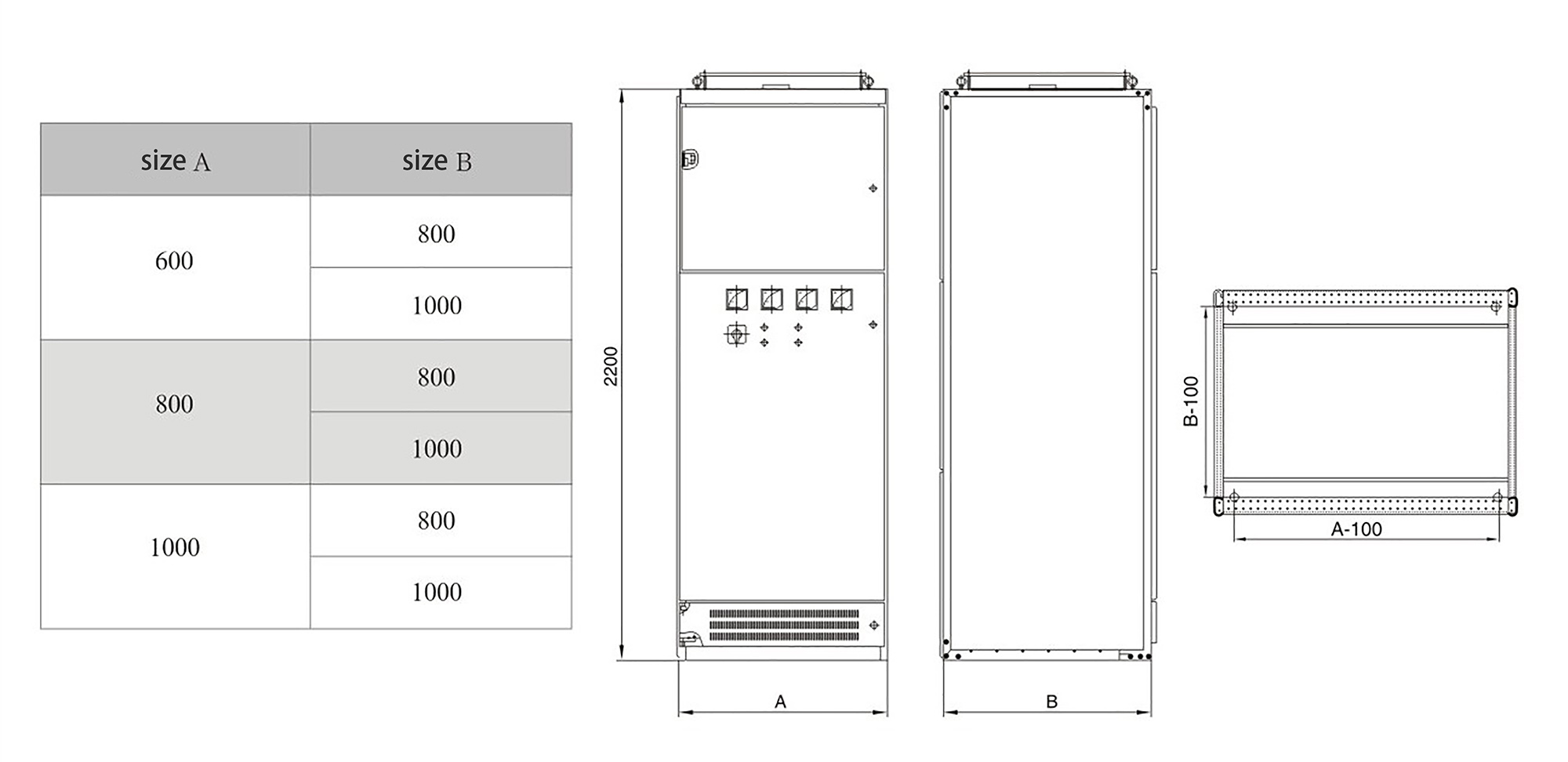

- The cabinet body of the GGD distribution cabinet adopts a universal cabinet design, with the frame constructed from 8MF cold-formed steel that is partially welded and assembled. The frame components and specialized supporting parts are produced and supplied by our company to ensure the precision and quality of the cabinet body.

- The design of the low voltage switchgear GGD fully takes into account the heat dissipation issues during operation. There are varying numbers of ventilation slots at both the upper and lower ends of the cabinet. When the electrical components inside the cabinet generate heat, the warm air rises and is expelled through the upper ventilation slots, while cool air continuously enters the cabinet through the lower slots. This creates a natural ventilation pathway from the bottom to the top of the sealed cabinet, effectively achieving heat dissipation.

- The cabinet doors are connected to the frame using pivot-type hinges, allowing for easy installation and removal.

- The surface of the cabinet body is treated using a high-pressure electrostatic powder coating process. This method enhances the durability and aesthetic appeal of the cabinet, providing a smooth and attractive finish while ensuring strong adhesion and resistance to wear and corrosion.

Technical Specification of Low Voltage Switchgear GGD

| model | Rated Voltage (V) | Rated Current(A) | Rated Short Circuit Breaking Current (kA) | Rated Short Circuit Withstand Current (1s)(kA) | Rated Peak Withstand Current (kA) | |

|---|---|---|---|---|---|---|

| GGD1 | 380(400)(660) | A | 1000 | 15 | 15 | 30 |

| B | 600(630) | |||||

| C | 400 | |||||

| GGD2 | 380(400)(660) | A | 1600(1500) | 30 | 30 | 63 |

| B | 1000 | |||||

| C | 1250 | |||||

| D | 600(630) | |||||

| GGD3 | 380(400)(660) | A | 3150 | 50 | 50 | 105 |

| B | 2500 | |||||

| C | 2000 | |||||

| D | 1600(1500) | |||||

| E | 1250 | |||||

| F | 1000 |

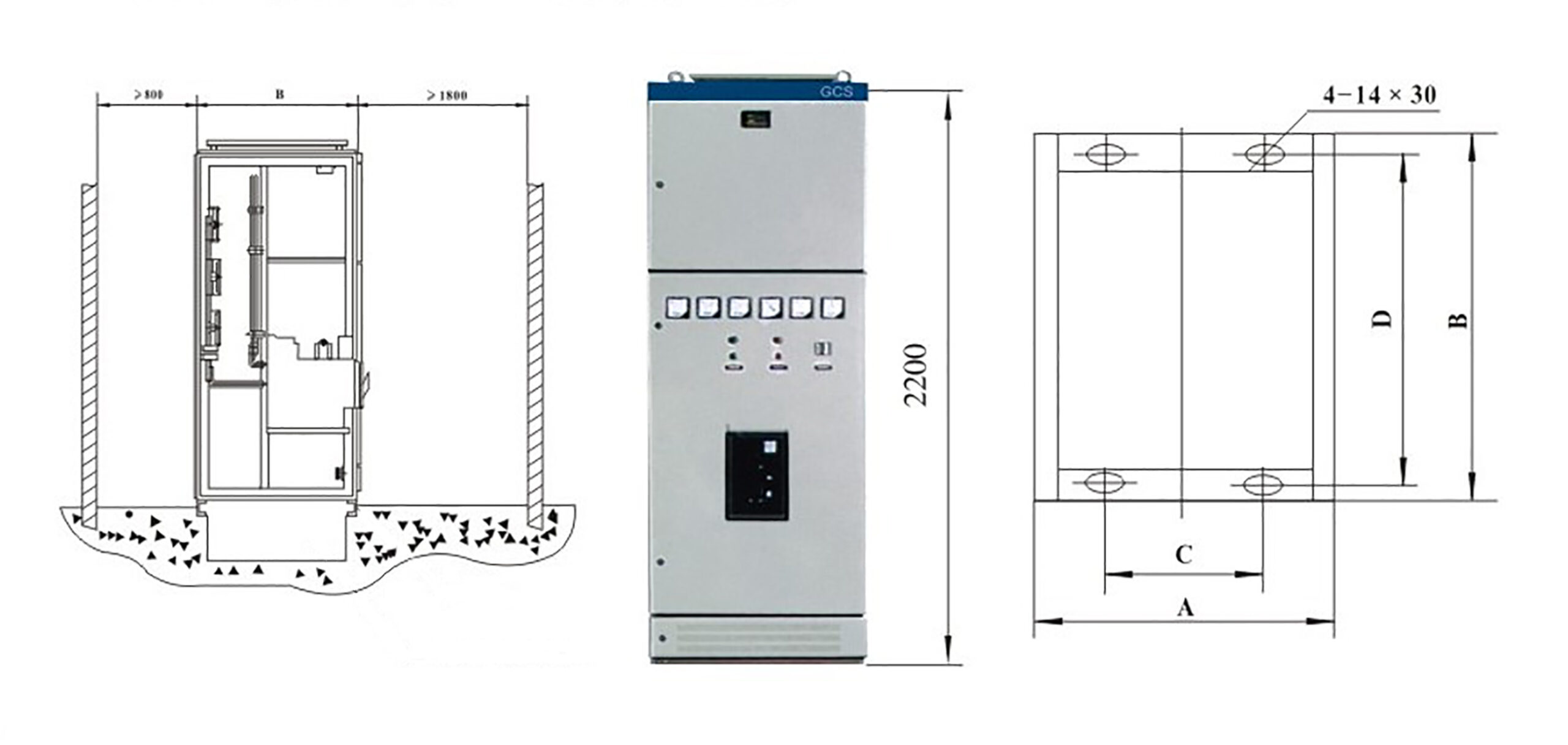

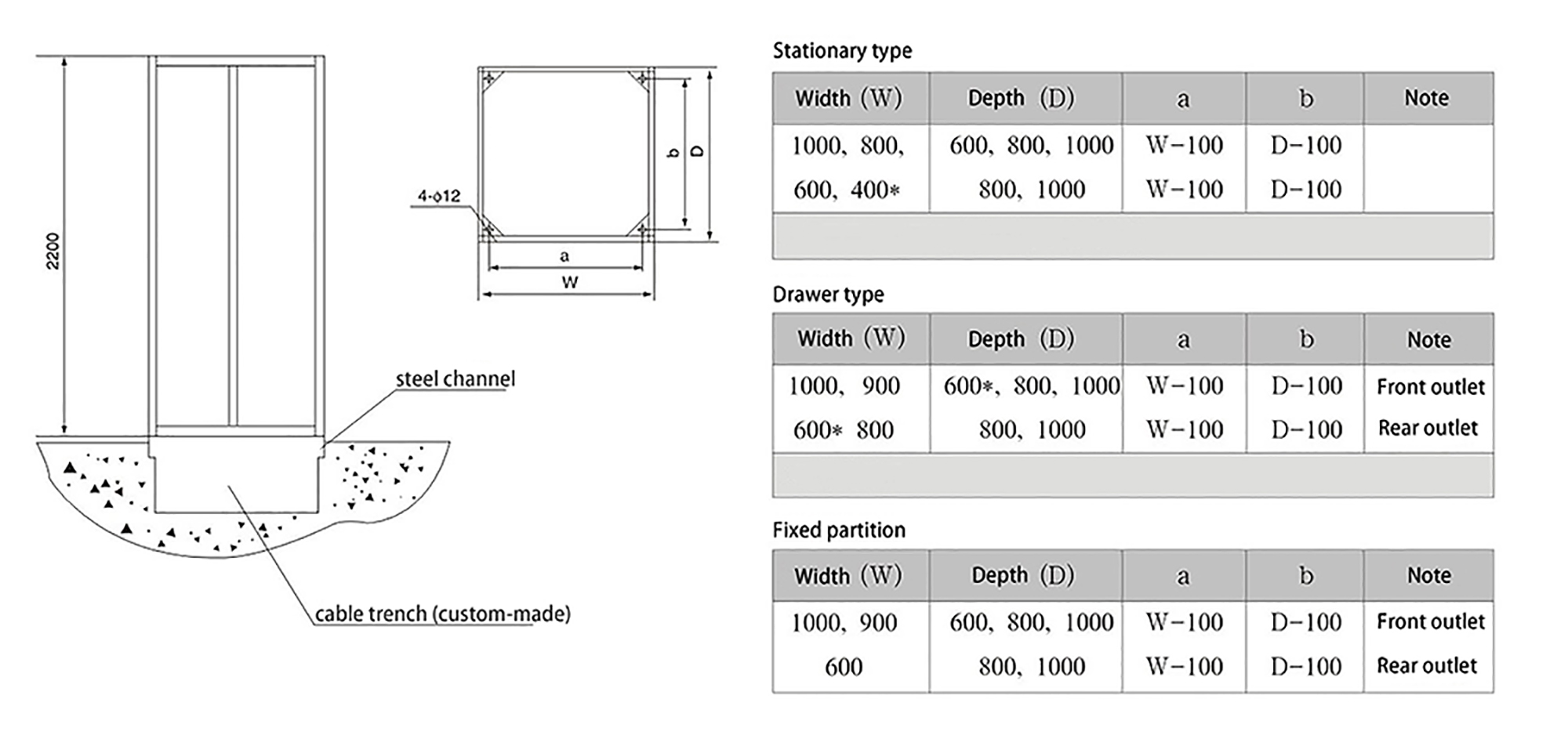

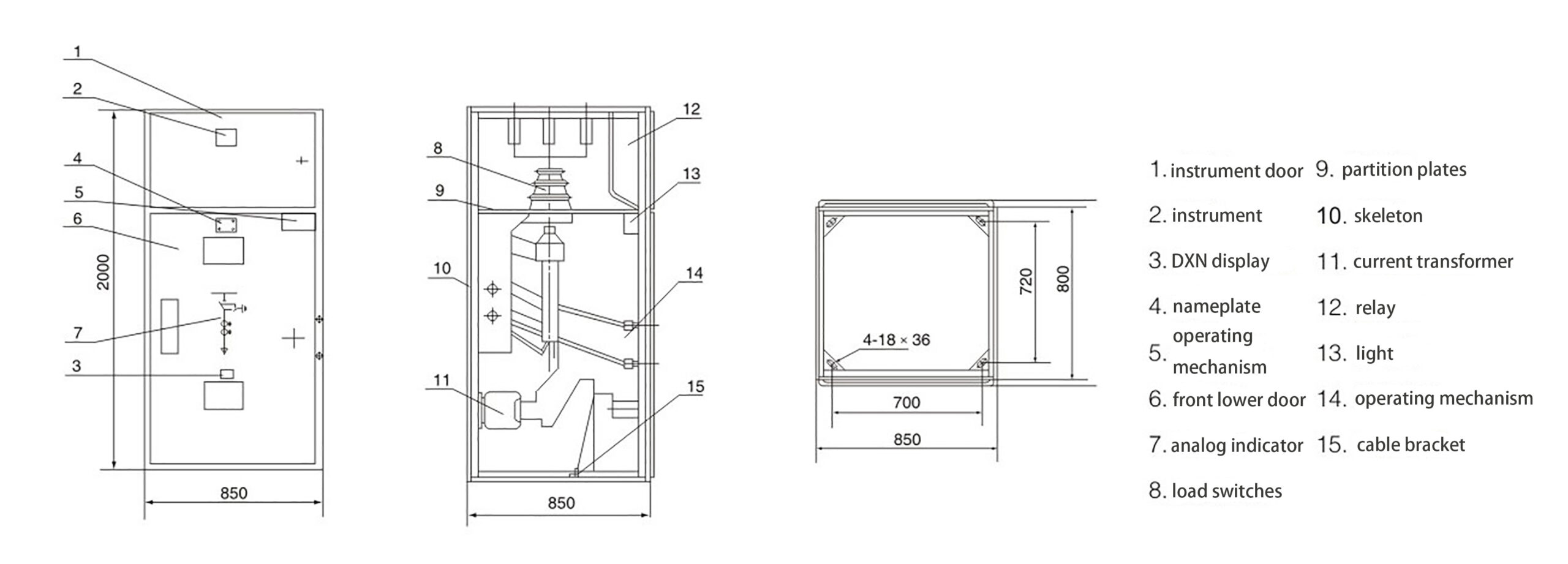

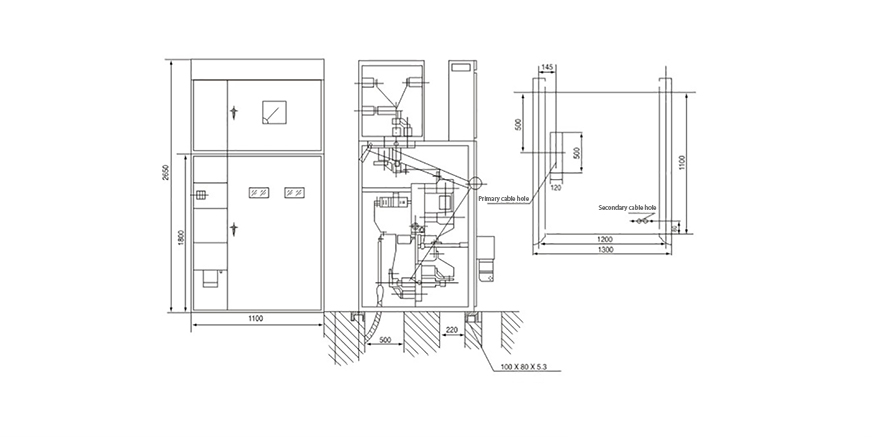

Drawing of Low Voltage Switchgear GGD

Get in Touch

- Sales Manager: Eric

- Phone: +86-15515007426

- Whatsapp: +86-15515007426

- Factory Address: Beiyoute Industrial Park, Xujia Gou Town, Yindu District, Anyang City