Single Phase Pole Mounted Transformer

50KVA Single Phase Pole Mounted Transformer

- Capacity:50KVA

- Cooling type: ONAN

- Frequency : 50/60HZ

- Efficiency: 99.11%

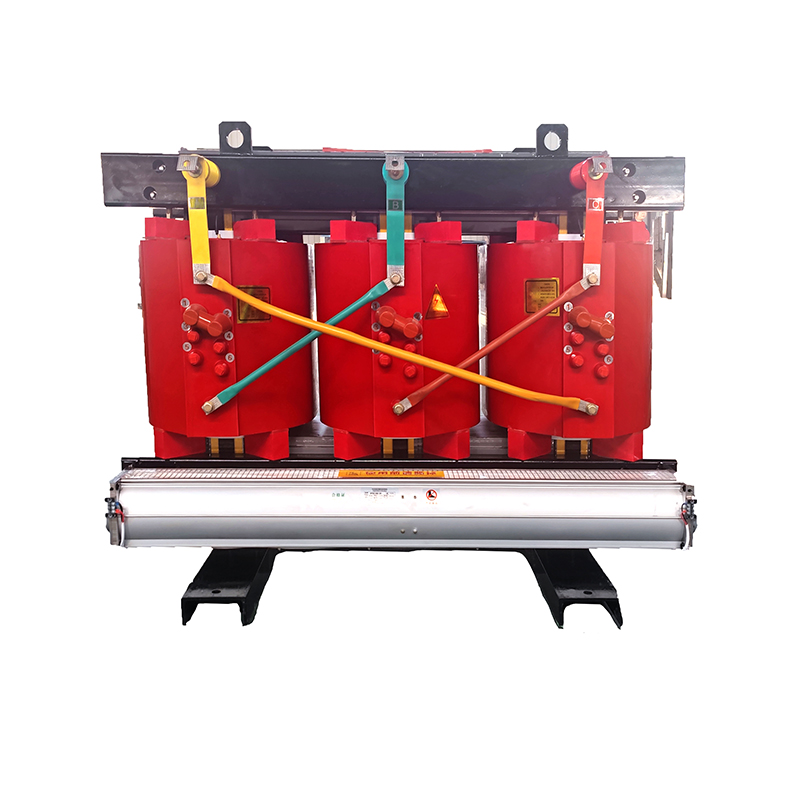

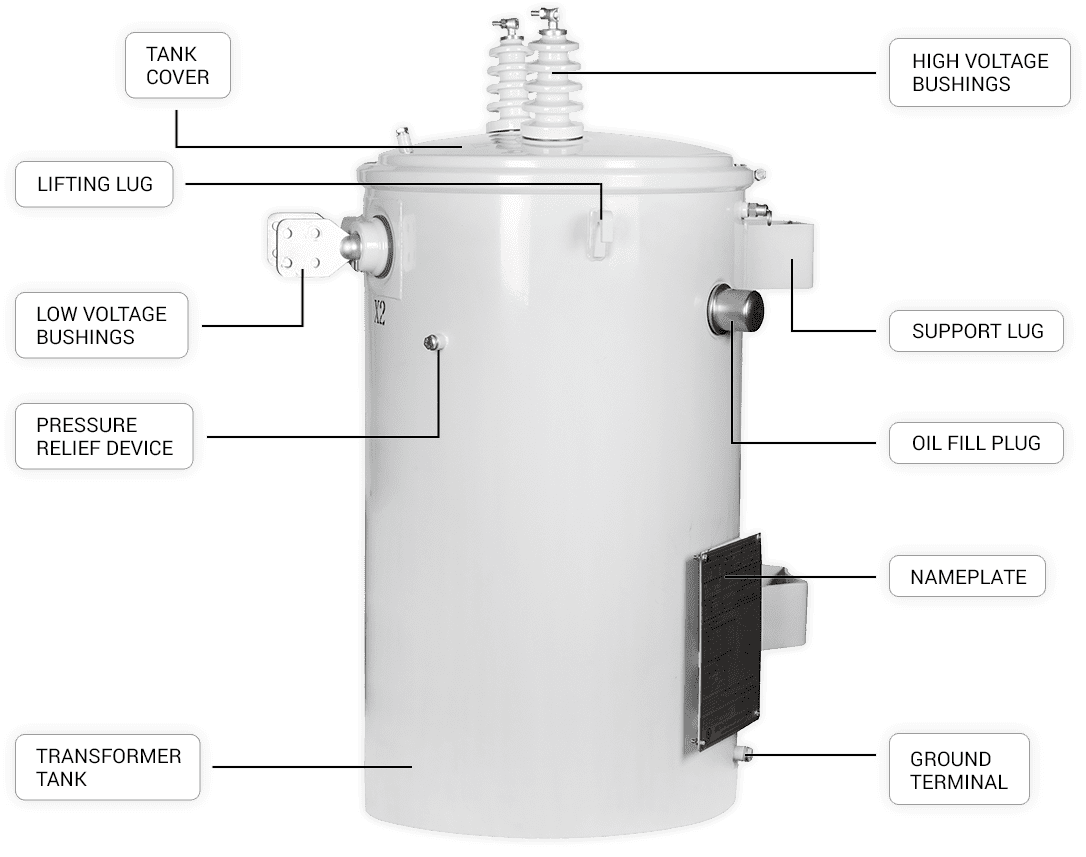

BYT 50KVA single-phase pole-mounted transformer is a compact and efficient electrical distribution transformer designed for residential and commercial applications. With a rated capacity of 50KVA, this transformer is suitable for converting high primary voltages to lower secondary voltages for safe and reliable power distribution. It features a durable pole-mounted design for easy installation and maintenance, making it ideal for outdoor use. The transformer is equipped with high-quality insulation materials and protective features to ensure safe and reliable operation. This transformer is a cost-effective solution for delivering stable power supply to various applications.

Introduction of 50KVA Single Phase Pole Mounted Transformer

The features and advantages of 50KVA single phase pole mounted transformer:

1) Compact Design: The pole-mounted transformer has a compact and space-saving design, making it suitable for installation in areas with limited space availability.

2) Easy Installation: The pole-mounted configuration allows for quick and easy installation on utility poles, reducing installation time and costs.

3) Outdoor Use: Designed for outdoor use, the transformer is built to withstand harsh weather conditions, ensuring reliable operation in various environments.

4) High Efficiency: The transformer is designed to deliver high efficiency in converting voltage levels, reducing energy losses and improving overall system performance.

5) Reliable Performance: With high-quality insulation materials and advanced protective features, the transformer offers reliable and safe operation, minimizing the risk of electrical faults and downtime.

6) Versatile Applications: The 50KVA single-phase transformer is suitable for a wide range of applications, including residential, commercial, and industrial power distribution.

7) Cost-Effective Solution: The transformer provides a cost-effective solution for power distribution, offering efficient voltage conversion and reliable performance at a competitive price point.

8) Low Maintenance: The transformer requires minimal maintenance, thanks to its durable construction and reliable components, reducing maintenance costs and downtime.

Technical Specification of Single Phase Pole Mounted Transformer

| Technical Specs | |

|---|---|

| Rating | 50 KVA |

| Type | Pole-Mounted Distribution Transformer |

| No. of Phases | 1 |

| Frequency | 60 Hz |

| Primary Voltage | 25/37.5 KV |

| Secondary Voltage | 120/240/480 V |

| Tapping Range | ±2 x 2.5% |

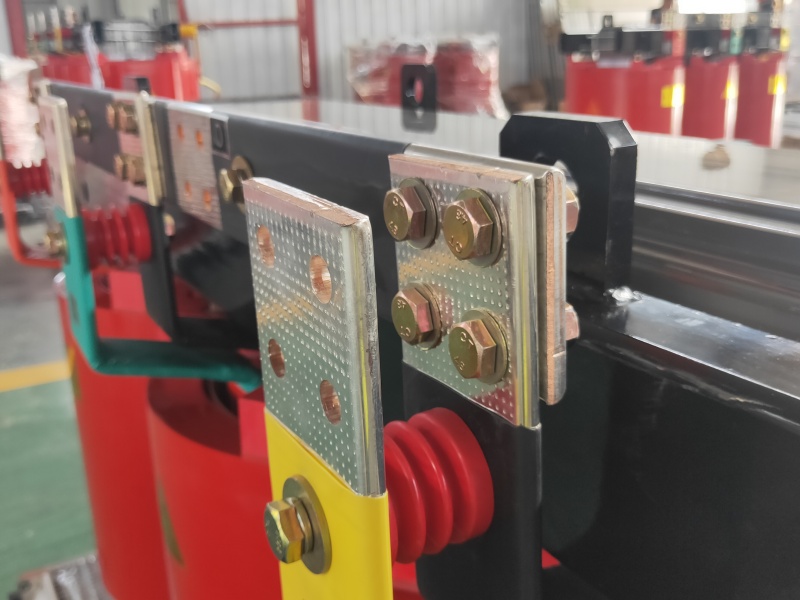

| Winding Material | Copper / Aluminum |

| Core Material | Grain Oriented Silicon Steel Sheet |

| Impedance | 1.5 – 4.5 % |

| Efficiency | 99.11% |

| Cooling Type | ONAN |

| Average Winding Rise | 55 °C, 55/65 °C, 65 °C |

| Fluid Type | Non-PCB Mineral Oil / FR3 Biodegradable |

| Tap Changer | Off-Load Tap Changer |

| IEEE Standards | C57.12.00, C57.12.20, C57.12.31, C57.12.35, C57.12.90, C57. 91 and C57.154 |

| NEMA Standard | NEMA TR 1 |

| Tank Coating | IEEE Std C57.12.31-2010 |

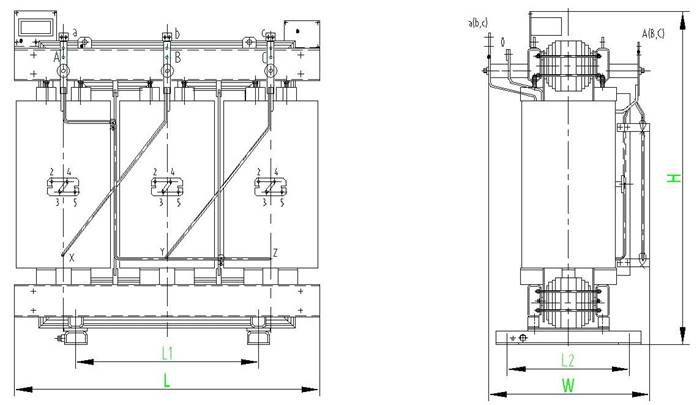

Drawing of Single Phase Pole Mounted Transformer

Get in Touch

- Sales Manager: Eric

- Phone: +86-15515007426

- Whatsapp: +86-15515007426

- Factory Address: Beiyoute Industrial Park, Xujia Gou Town, Yindu District, Anyang City