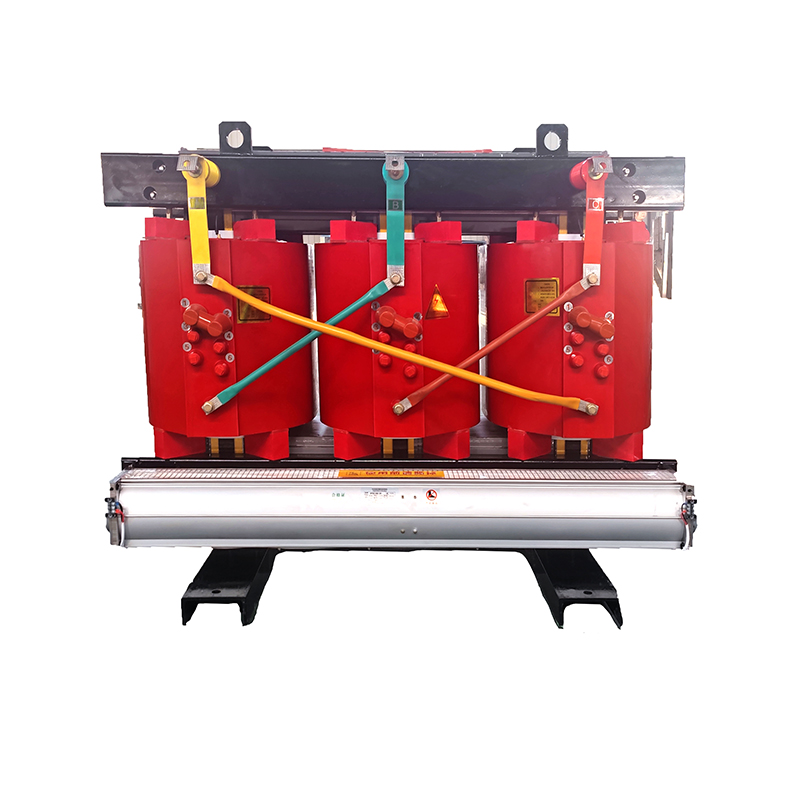

SCB Series Dry Type Transformer

BYT manufacture a complete range of three phase distribution transformers, including oil-immersed type & cast resin dry-type transformer, we always designed with increased margins of safety and reliablity, and meet the IEC60076, IEEE Std.

Three phase resin-cast dry-type distribution transformer is with features of low loss, compact and light weight, low noise level, clamp-proof,anti-fouling, high mechanical strength, flame resisting, strong overload ability and low partial discharge quality, they are application to power transmission and distribution system, hotel, restaurant, commercial building, stadiums, chemical plants, stations, aiports, offshore drilling platforms, especially to heavy load centers and places with special fire protection requirements.